Acrylic, also known as plexiglass, is a popular plastic material beloved for its clarity, strength, and design versatility. From signage and displays to jewelry, decorations and industrial prototyping, acrylic is one of the most laser‐friendly materials—if you know how to cut it. In this comprehensive guide—focusing on the Creality Falcon ecosystem—you'll learn everything from selecting acrylic types to fine‐tuning your laser engraver, choosing the right settings, troubleshooting common issues, and getting inspired with creative applications.

Whether you're a hobbyist, maker, or a growing business, this master guide covers:

-

The science behind acrylic laser cutting

-

Best acrylic types and how they behave

-

Which laser machines deliver optimal results

-

Step‐by‐step process for cutting clean acrylic

-

Recommended settings by thickness and material

-

Smart safety practices

-

Creative project ideas to spark inspiration

-

FAQs and pro advice to avoid rookie mistakes

Can You Cut Acrylic Using a Laser?

Yes—you can—and you should! Cutting acrylic with a laser cutter (especially CO₂ lasers) delivers ultra‐clean edges, intricate cuts, and minimal burrs. Unlike mechanical cutting, laser cutting vaporizes the material precisely, ensuring smooth finishes and accurate profiles. The results often require no sanding or polishing.

Laser cutting works great for:

-

Signage and displays (business signs, exhibition panels)

-

Decorative items (ornaments, cake toppers, awards)

-

Jewelry components and fashion accessories

-

Functional prototypes like brackets or housings

Creativity meets precision when acrylic combines with laser technology.

How Acrylic Laser Cutting Works

Laser cutting harnesses the power of a focused beam guided by design files:

-

Import Vector Design – your design path (SVG, DXF, AI) tells the machine exactly where to cut.

-

Laser Focus – a high‐power CO₂ laser heats the acrylic until it vaporizes.

-

Cut Groove Formation – the beam immediately removes material, leaving a polished cut edge.

-

Engraving Layers – to engrave, just reduce power/speed so you only remove the surface layer for detailed surface graphics.

The magic is in heat control—vaporization, not melting—which yields that signature glossy edge.

Types of Acrylic—Choose Wisely

Cast Acrylic

-

Produced by pouring liquid acrylic into molds

-

Offers excellent optical clarity and edge quality

-

Engraves cleanly, with full polish on cut edges

-

Ideal for fine, decorative and visual work

Extruded Acrylic

-

Made by extruding sheets through rollers

-

More cost‑effective and easier to cut

-

Edges may show slight frosting or texture

-

Better suited for utility parts where edge finish isn’t critical

Tip: For critical polished items like signage or jewelry, select cast acrylic. For prototyping or structural projects, extruded acrylic may be more budget‑friendly.

Which Laser Machine Is Best for Cutting Acrylic?

CO₂ lasers operating at a wavelength around 10.6 µm match acrylic absorption peaks—making them the go-to choice.

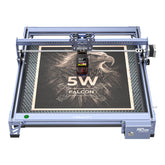

Here are high‑performance Creality Falcon options:

-

The creality falcon a1 is an excellent entry point for light acrylic work and small signs.

-

For medium scale or frequent use, the creality falcon 5w provides more consistent cutting power.

-

Stepping up, the falcon2 22W delivers fast, deeper cuts.

-

For advanced projects, the creality falcon 2 pro brings enclosed design, autofocus, and high-power cutting ideal for thick acrylic.

Each of these offers different throughput and usability advantages to match project scale.

How to Laser Cut Acrylic: Step‑by‑Step

1. Prepare the Acrylic Sheet

-

Remove any dust or dirt.

-

Ideally leave protective film on during cutting to avoid scratching edges—especially helpful for larger pieces.

-

Lay the sheet flat and secure it to prevent shift or warping.

2. Upload Your Design

Use design software like LightBurn, which supports vector import and layering. Setup your file with proper line types (e.g. RED for cut, BLACK for engraving).

3. Configure Cutting Settings

Use pre‑configured material profiles or manually set:

-

Power: scale by thickness (e.g. 10 W per mm is a rough guide)

-

Speed: slower for deeper cuts (e.g. 300–500 mm/min for 6–10mm acrylic)

-

Frequency: 5,000–20,000 Hz for cast, ≤5,000 Hz for extruded

-

Air Assist: always on, helps blow away fumes and keep lens clean

4. Start the Cutting Process

Run a small test piece before full production. Confirm clean edges and adjust as needed. If you see residue or flame, tweak power and speed.

5. Post Processing

Once cutting is done:

-

Peel off protective film carefully

-

Polish edges if needed with a flame or fine paper

-

Clean off smoke marks with a mild cleaner or alcohol

Recommended Laser Settings by Acrylic Thickness

| Acrylic Thickness | Typical Power (W) | Speed (mm/min) | Frequency (Hz) |

|---|---|---|---|

| 2 mm | 20–30 | 1000–1500 | 8,000–20,000 (cast) |

| 4 mm | 40–60 | 800–1200 | 8,000–15,000 (cast) |

| 6 mm | 60–80 | 400–800 | 5,000–10,000 (cast) |

| 10 mm | 80+ | 300–500 | ≤5,000 (extruded) |

Note: Your actual power and speed vary based on laser output quality, acrylic pigmentation, and ventilation. Always conduct test burns on scrap.

Quality Troubleshooting & Pro Tips

-

Edges burn/darken excessively? Slow your cut or reduce power. Use multiple passes rather than blasting through.

-

Edge frosting or cloudiness? You may be using extruded acrylic or too low power. Try increasing power or smoothing the finish (fire polishing).

-

Material eye discoloration? Too hot or slow—adjust settings and ensure adequate ventilation/air assist.

-

Inconsistent depth or shape? Check focus is properly calibrated and the material is flat. Ensure engraving bed is level.

-

Flame flares or smoke? Too much power or speed is too low. Air assist must be enabled throughout the cut.

Creative Acrylic Project Ideas

Laser cutting acrylic unlocks many creative and practical possibilities:

-

Custom signs & logos: durable, illuminated or layered signage for offices or shops

-

Jewelry and earrings: precision geometric shapes with color backing

-

Awards & plaques: engraved or cut pieces in acrylic mounted on base

-

Cake toppers & ornaments: festive shapes with glossy edges

-

Keychains and tags: custom shapes, names or brand logos

-

Decorative LED lighting panels: layered acrylic designs lit from underneath

-

Wedding table names / place cards: engraved acrylic cards with a polished look

Each idea benefits from clean lines and high contrast—achievable with the right settings and materials.

Safety Tips & Best Practices

-

Ventilation is essential: acrylic burning releases fumes and vapors—use fume extraction or run in a well-ventilated space.

-

Wear laser-rated goggles—even low‑power machines emit powerful invisible light.

-

Never leave the machine unattended—acrylic can ignite.

-

Ensure fire safety: keep a fire extinguisher nearby when cutting thicker sheets.

-

Maintain your lens and mirrors—clean them regularly to preserve beam quality and avoid edge artifacts.

Why the Creality Falcon Ecosystem?

As part of the creality falcon family, each laser machine is designed with:

-

Stable build for long precision runs

-

User-friendly software compatibility (LightBurn)

-

Expandable accessories like rotary attachments for cutting cylindrical shapes

-

Safety features on higher‑end models (enclosed chamber, airflow systems)

-

Scalable power options from hobby to semi‑professional ranges

The creality falcon a1 is perfect for lightweight acrylic signage and crafts. When you need faster throughput or thicker cuts, stepping up to a creality falcon 5w or falcon2 22W delivers more reliability. For thicker, production‑grade or commercial applications, the creality falcon 2 pro offers autofocus, enclosed cabinet, and higher cutting capacity.

Final Thoughts

Laser cutting acrylic with a CO₂ laser is a precise, efficient, and visually impressive way to fabricate clean acrylic components. From thin decorative pieces to structural signage, the edges are polished and the cuts accurate—no mechanical finishing required.

By choosing the right acrylic type, using a reliable laser engraver, optimizing your settings, and following safety best practices, you’ll achieve professional results every time. Whether you’re crafting gifts, designing prototypes, or launching a small product line, Creality Falcon machines empower you to turn design ideas into polished creations.

Explore more at creality falcon, and unlock your laser creativity today.