Understanding Laser Air Assist: Enhancing Efficiency and Quality with CrealityFalcon Air Assist

Understanding Laser Air Assist: What is it?

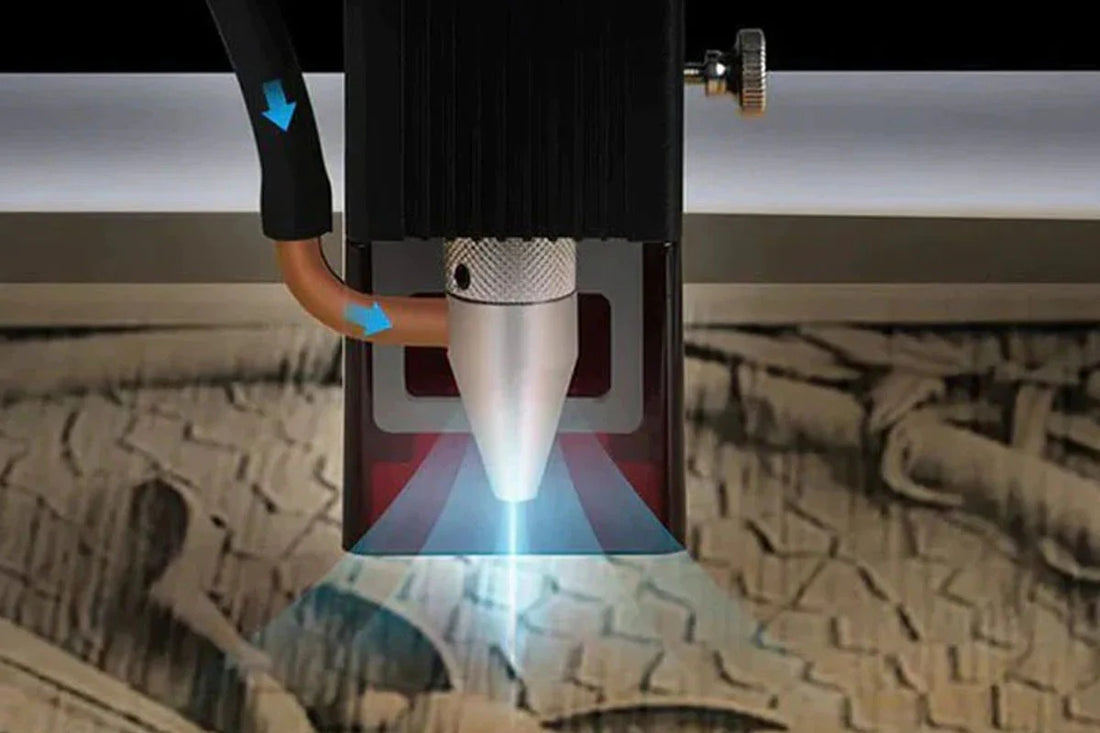

Laser Air Assist is a feature typically found in laser cutting and engraving machines. It involves the use of a concentrated stream of air that is directed at the point where the laser hits the material being worked on. This air stream serves multiple purposes in the laser engraving or cutting process, including cooling the material, reducing flames, and blowing away debris.

The Role of Laser Engraving Air Assist in Laser Machines

Performance-wise, the Falcon 2 outperforms the Falcon CR. It offers a more stable performance and can cut through thicker materials with ease. The Falcon 2 also operates at higher speeds, enhancing the engraving and cutting effects.

HOW DOES LASER AIR ASSIST WORK?

Laser air assist works by directing a stream of compressed air right at the point where the laser beam interacts with the material. This action helps in cooling the area, preventing potential flare-ups and removing the debris produced during the cutting or engraving process.

Profiting From Laser Air Assist

Laser air assist comes with numerous benefits that contribute to improved quality of work, profitability, and safety. These include:

-

Profitability: By ensuring a cleaner and smoother finish, air assist can significantly enhance the quality of the final product, hence increasing its market value.

- Cleaner Finishing: The air stream helps in blowing away smoke and dust, thus preventing them from settling on the material and ensuring a cleaner finish.

- Lower Production Cost: By reducing the likelihood of damage due to heat and debris, air assist can significantly lower the overall production cost.

- Improved Efficiency: With air assist, the laser machine can operate more efficiently as it prevents the build-up of debris that could potentially interfere with the machine's workings.

- High Edge Quality: Air assist also improves the quality of the edges of the engraved or cut material, making them smoother and more precise.

- Increased Safety: By reducing the risk of fire hazards associated with the laser engraving or cutting process, air assist significantly increases the safety of operations.

Dangers of Ignoring Air Assist in Laser Engraving

Not using air assist can pose several risks, including increased chances of a fire, poor quality of work due to the accumulation of smoke and dust, potential damage to the laser machine, and increased production cost.

Conclusion

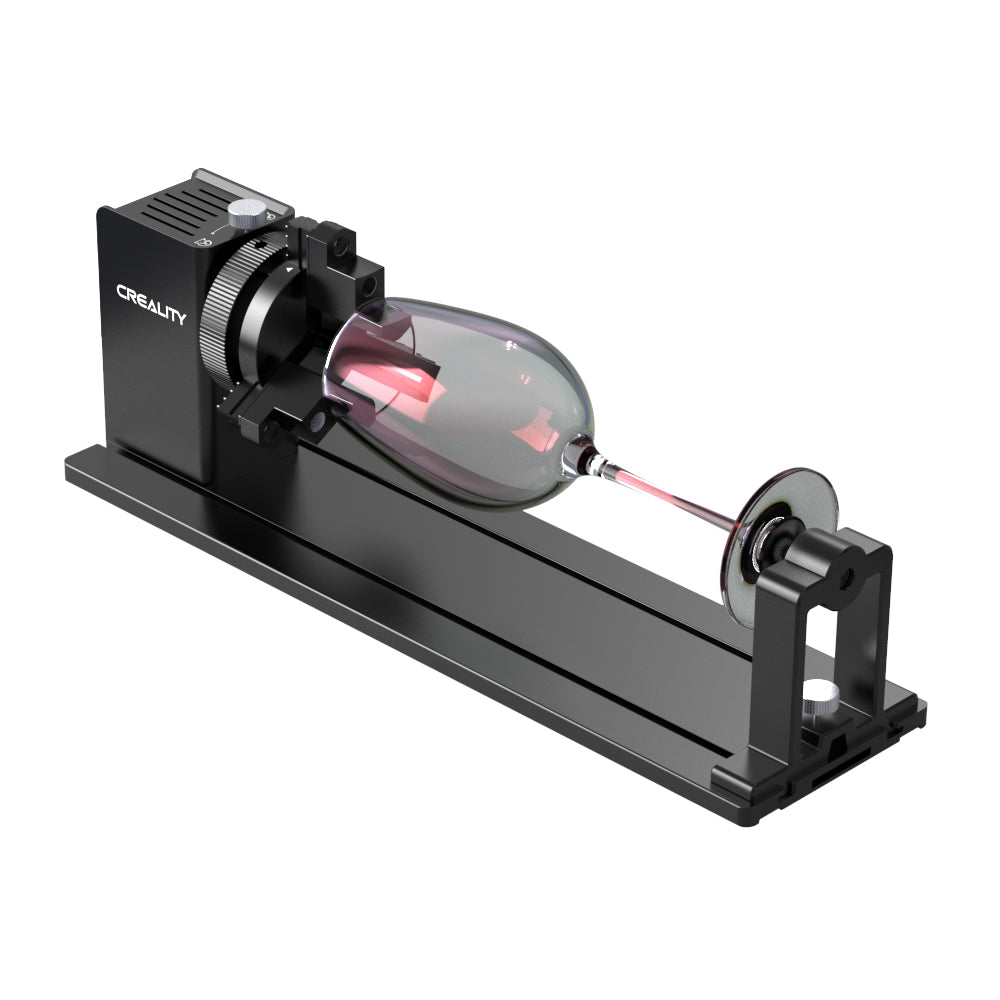

Laser air assist is an essential feature for any laser engraving or cutting machine. It not only improves the quality of work but also enhances safety and profitability. One such product that offers these benefits is the CrealityFalcon Air Assist.

The CrealityFalcon Air Assist Kit comes with powerful airflow that effectively blows away smoke and dust, keeping the material surfaces clean. It operates with low working noise, making it convenient to use in various settings. It's easy to use, and it is designed for the Falcon Series Laser Engraving Machine , making it a suitable addition to enhance your laser engraving or cutting operations.

-

Understanding Laser Air Assist: What is it?

-

The Role of Laser Engraving Air Assist in Laser Machines

-

HOW DOES LASER AIR ASSIST WORK?

-

Profiting From Laser Air Assist

-

Dangers of Ignoring Air Assist in Laser Engraving

-

Conclusion