Introduction: Two Popular Maker Technologies

Over the past decade, both laser engraving and 3D printing have revolutionized the maker community. They give creators, educators, and entrepreneurs new ways to prototype, customize, and produce products on demand.

But they are not the same. Laser engraving removes material with a high-powered beam of light, while 3D printing builds objects layer by layer. Choosing between the two depends on your budget, materials, and project goals.

What Is Laser Engraving?

Laser engraving is a subtractive manufacturing process. A focused beam of light burns or vaporizes material to mark, etch, or cut.

-

Best suited for: Personalization, signs, jewelry, craft items, small business production.

-

Common materials: Wood, acrylic, leather, glass, coated metals, stone, paper.

-

Example hardware: The Falcon A1 Pro 20W Dual-laser Engraver, which cuts 10mm wood and engraves fine details with IR precision.

Laser engravers excel at precision, speed, and finishing touches.

What Is 3D Printing?

3D printing is an additive manufacturing process. A digital design is sliced into layers, then material (usually plastic filament or resin) is deposited layer by layer until the object is complete.

-

Best suited for: Prototyping, engineering models, toys, replacement parts.

-

Common materials: PLA, ABS, PETG, nylon, resins.

-

Advantages: Ability to create complex 3D geometries that traditional methods can’t replicate.

3D printing is ideal for building functional objects from scratch, but finishing may require sanding, painting, or post-processing.

Key Differences Between Laser Engraving and 3D Printing

| Feature | Laser Engraving | 3D Printing |

|---|---|---|

| Process | Subtractive (removes material) | Additive (builds layer by layer) |

| Materials | Wood, acrylic, leather, metal, glass | PLA, ABS, resin, nylon |

| Applications | Personalization, signs, etching, cutting | Prototyping, functional models, replacement parts |

| Speed | Very fast for engraving/cutting | Slower, depends on object size |

| Detail | Extremely fine (0.03mm spot with IR laser) | Layer resolution ~0.1–0.2mm |

| Cost of Entry | €600–€1500 for diode engravers | €200–€1000 for FDM printers |

| Learning Curve | Easy with software like LightBurn | Moderate (slicing, supports, calibration) |

When to Choose Laser Engraving

Laser engraving is the better option if you want to:

-

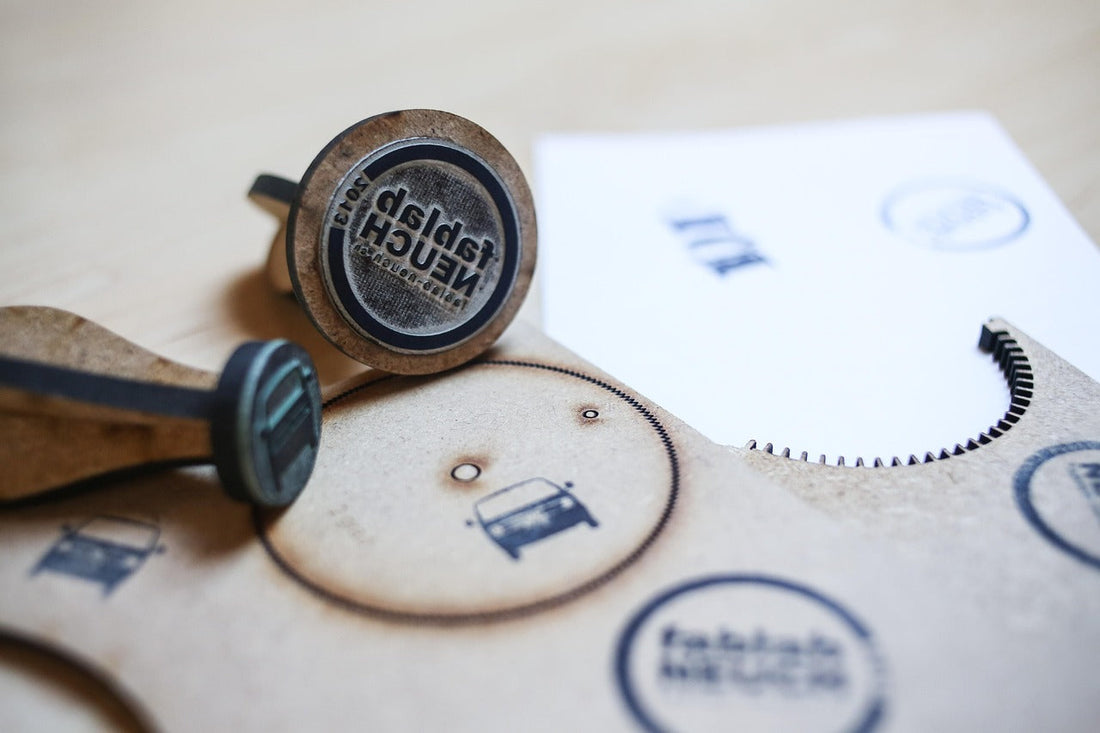

Personalize products like jewelry, leather, or gifts.

-

Cut wood, acrylic, or cardboard for crafts and signage.

-

Start a small engraving business (Etsy, local shops).

-

Work with over 350 materials, from paper to stainless steel.

With machines like the Falcon2 Pro 40W Enclosed Laser Engraver, you can scale up to more demanding workloads safely.

When to Choose 3D Printing

3D printing is the right choice if you want to:

-

Prototype mechanical parts quickly.

-

Build complex 3D shapes not possible with engraving.

-

Print household items, replacement parts, or custom tools.

-

Experiment with affordable entry-level machines.

It’s especially strong for functional models rather than surface decoration.

Can Laser Engraving and 3D Printing Work Together?

Yes! Many creators combine the two technologies:

-

3D print an object → then add laser engraving for personalization (logos, text, decoration).

-

Laser cut acrylic or wood → then combine with 3D printed connectors for functional designs.

The two technologies complement each other, making them a powerful duo for makers and businesses.

Cost and Maintenance Considerations

-

Laser Engraving: Slightly higher entry cost, but faster ROI for business use. Needs cleaning of optics, airflow systems, and lens calibration.

-

3D Printing: Cheaper entry, but ongoing material costs (filament/resin). Requires maintenance of extruder, bed leveling, and print quality tuning.

If your goal is profit (custom products, personalization), laser engraving often pays off faster. If your goal is innovation and prototyping, 3D printing makes more sense.

Conclusion: Which Technology Fits Your Needs?

Both laser engraving and 3D printing are powerful tools — but they serve different purposes:

-

Choose laser engraving if you need speed, precision, and personalization across 350+ materials.

-

Choose 3D printing if you want to build objects from scratch and prototype complex designs.

-

Use both together if you’re running a maker workshop, classroom, or creative business.

👉 Ready to explore engraving? Check out the Creality Falcon collection and find the perfect laser engraver for your needs.